Delay Scorching Vulcanizing Accelerator for IR Tyre Actmix DCBS-70PR

Delay Scorching Vulcanizing Accelerator DCBS

Long Curking Time Vulcanzing Accelerator DCBS

Delay Scorching Vulcanizing Accelerator for IR Tire

N,N-Dicyclohexyl-2-benzothiazolsulfene amide

C19H26N2S2

M.W. 346.55

CAS No.: 4979-32-2

EINECS No.: 225-625-8

PROPERTIES:

Compared with CBS, TBBS, MBS,DCBS scorch time and curing time is long, modulus of vulcanized rubber is low. The homologous physical properties to obtain need higher dosage. to increase the amound to obtain the corresponding properties. Usually used in the steel wire rubber formula to improve the bonding strength. DCBS can delay scoring, improve process safety. DCBS-80 can make the rubber compound with long scorching, safety processing and high curing speed. It can be used alone in the low sulphur vulcanization, also can be used together with dithiocarbamate salts or thiuram accelerators, the vulcanizates has good aging resistance and compression set resistance.

DOSAGE:

For NR: primary accelerator: 0.5-1.0phr with 2.5-3.5phr sulfur;

For SBR: 1.0-1.5phr combine with 0-0.2 thiuram accelerators and 1.5-2.5phr sulfur.

TYPICAL VALUES:

Melting point:Min 97℃

Purity:Min 98%

Free amine:Max 0.4%

Ash content: Max 0.3%

Heat loss:Max 0.3 %

63μm sieve residue:Max 0.5%

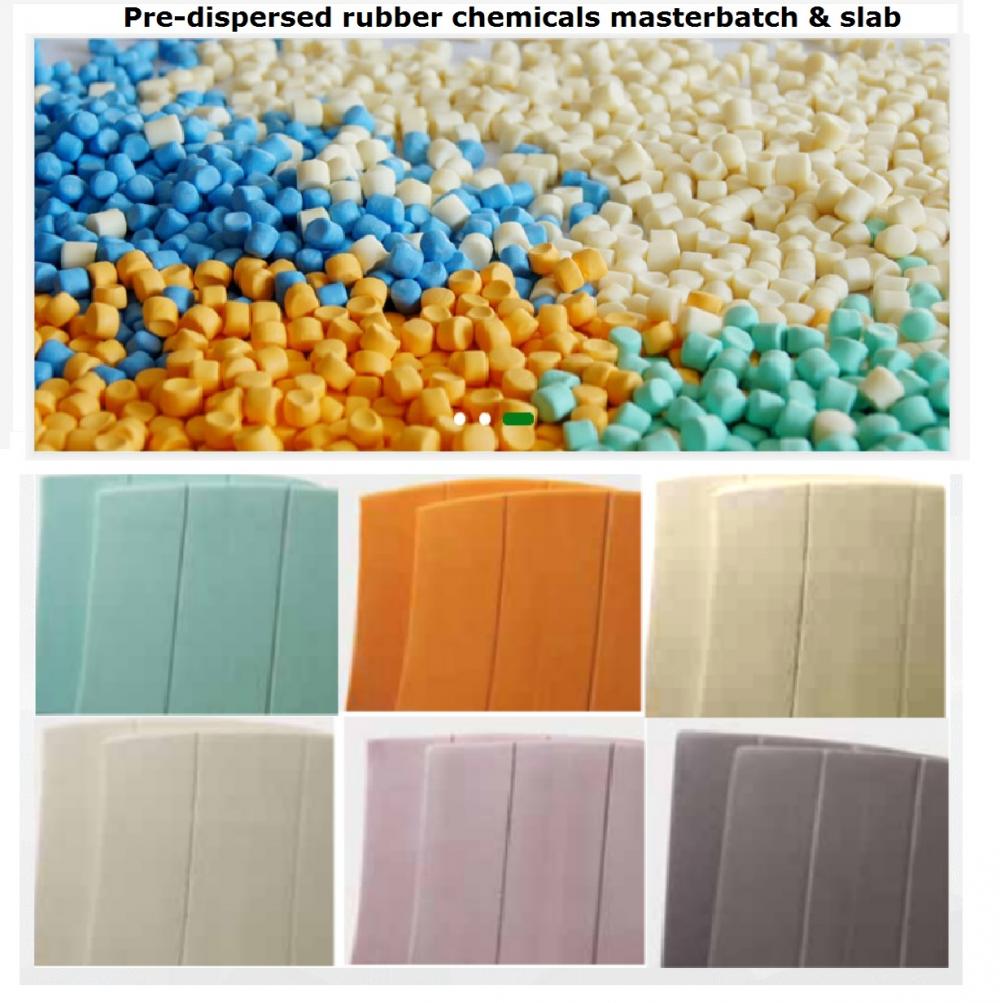

| Product | Active Content (%) | Appearance | Filtration (μm) | Binder | Sulfur Content (%) | Density (g/cm3) |

| Actmix DCBS-70PR | 70 | Beige slab | -- | Natural Rubber | -- | -- |

| * Binder type can be customized. Except Natural Rubber, others binders, such as EPDM, NBR, SBR, AR, ECO also can be available for. |

Actmix DCBS-70PR assist customers to achieve better economical performance:

1. Homogeneous dispersion & better quality & scrap rate reduction

2. Higher productivity & active material reduction

3. Increase of the reliability

4. Heathly work improvement & reduction of the PPE costs & ease of handling

5. Improvement of cleaning process & lower environmental footprint

6. Wider compatibility with other elastomers.

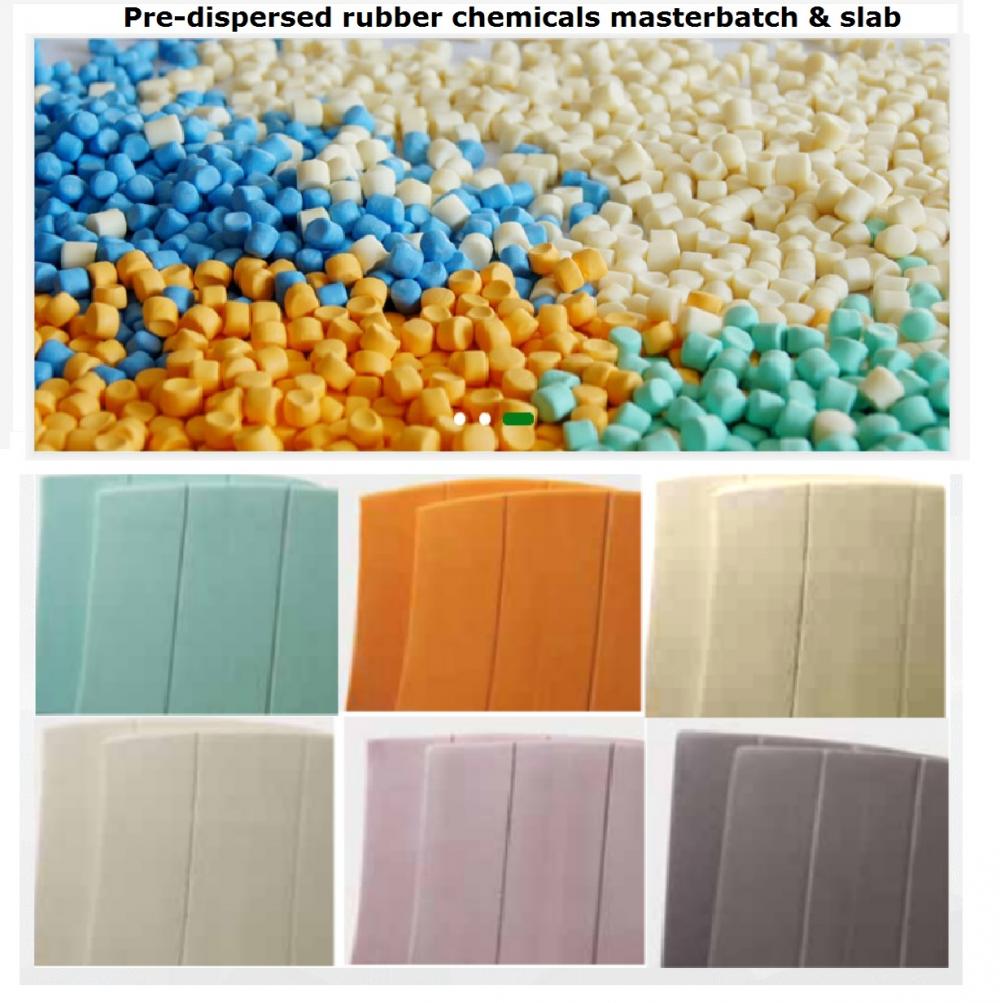

Actmix Pre-Dispersed Rubber Chemicals masterbatch applications:

1. Automotive rubber sealing strip

2. Technical rubber parts: wiper blades, seal, hose, belt, anti-vibratory etc.

3. Rubber tires

4. Rubber shoes soles, boots

5. Rubber cables

6. Rubber sports equipment & articles